At 00:50 on December 13, 2022, after 28 hours of continuous effort, the pullback operation for the first offshore pipeline crossing of the Weibei Pipeline Development Project was successfully completed.

The natural gas from the Weizhou Terminal is primarily used for power generation and supplying downstream users for LNG production. The remaining gas, however, can only be flared, leading to resource wastage and environmental concerns. In support of China’s goal to achieve "carbon peak and carbon neutrality", and in response to CNOOC's green (China National Offshore Oil Corporation) and low-carbon development strategy, as well as the calls from the Guangxi Zhuang Autonomous Region and Beihai City government to enhance the supply of clean natural gas, the Weibei Pipeline Development Project was initiated to contribute to the green and clean economic development of Beihai City.

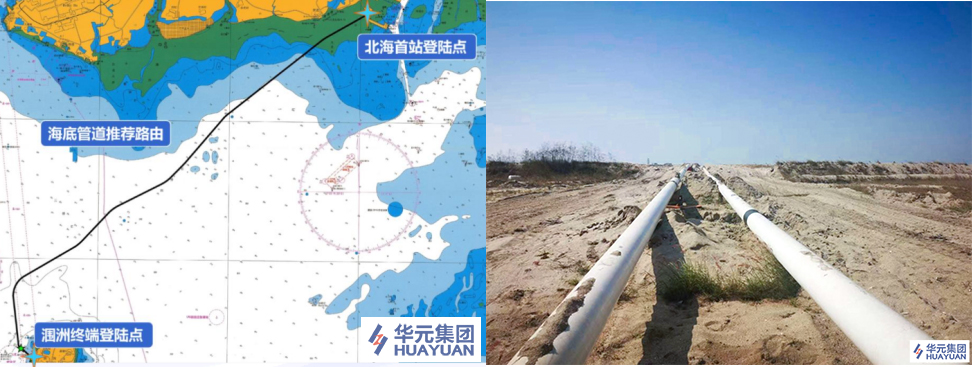

This subsea pipeline crossing work is the first station of the Weibei Pipeline Development Project, located in the Tieshangang Industrial Zone of Beihai City, Guangxi Province. The pipeline has a diameter of D323.9 mm, with specifications SMLS D323.9×15.9 API 5L PSL2 X65. The total horizontal length of the project is approximately 1,413 meters, including 1,013 meters of horizontal directional drilling (HDD) and a 400-meter compensation section.

On the entry point, a section of the pipeline passes through a backfill layer with loose soil condition. To ensure smooth construction, a casing was installed for isolation and support.

Due to the insufficient length of the pipeline prefabrication site, a "two-in-one" pullback method was used. The pipeline was prefabricated in two sections on land, with lengths of 829.781 meters and 610.341 meters respectively, resulting in a total prefabrication length of 1,440.122 meters.

To further advance the project, the owner organized an expert review meeting on August 30, 2022, to evaluate the implementation plan and safety risk analysis for the subsea pipeline crossing of the Weibei Pipeline Development Project.

The successful review provided reliable technical guidance for the subsequent construction, ensuring high-quality and efficient progress.

After the commencement of the subsea pipeline crossing, construction was paused on October 20 after completing casing installation, subsea pipeline welding, anti-corrosion treatment, pressure testing, and gauging. Upon receiving the resumption notice on November 14, Huayuan swiftly organized a mobilization and safety inspection, ensuring a safe restart of the project. Adjustments were made to personnel and work progress, with careful tracking of each construction milestone to ensure the project was completed smoothly.

During the pullback, the pipeline's entry angle was 18°. To ensure that the pipe head angle matched the entry angle into the casing, pipeline supports were used to elevate the pipeline. The height of the supports was adjusted based on the actual site conditions, with the highest support reaching 5.53 meters to maintain the pipeline's overall curvature before entry. Rollers were used to transport the rest of the pipeline.

Before the pullback, the owner conducted a Job Safety Analysis (JSA) and on-site technical briefing, implementing site supervision and safety measures.

During the pullback, the project team meticulously planned and organized the operation. All participants overcame challenges such as significant temperature differences between day and night, strong winds, and cold weather to ensure the successful completion of the project.

The completion of this HDD subsea pipeline crossing marks the successful conclusion of the first major challenge in the Weibei Pipeline Development Project by Huayuan. This achievement lays a solid foundation for the timely commissioning of the project and provides valuable experience for land-to- sea directional drilling construction, contributing significantly to the high-quality development of directional drilling operations.